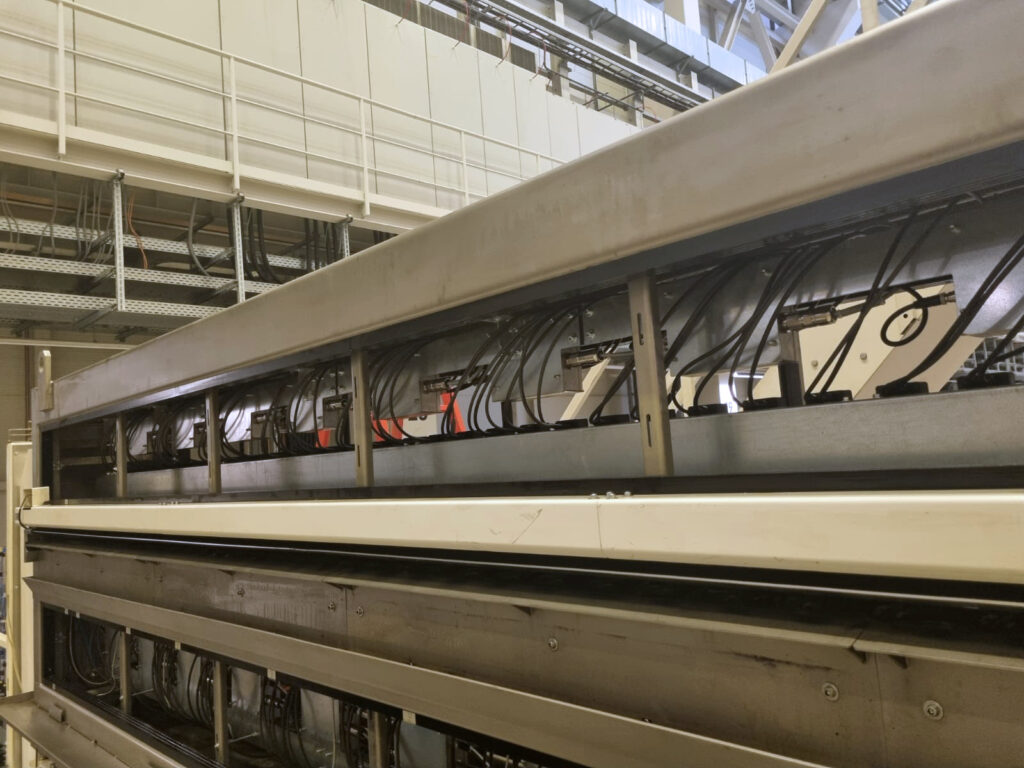

Retrofit with Eckardt: all or nothing, black or white – usually the optimum solution lies somewhere in between. This is what a long-standing customer from the automotive industry had in mind when he commissioned us to upgrade his Eckardt EOS 3 series spray system. This allows blanks up to 4100 mm wide to be oiled.

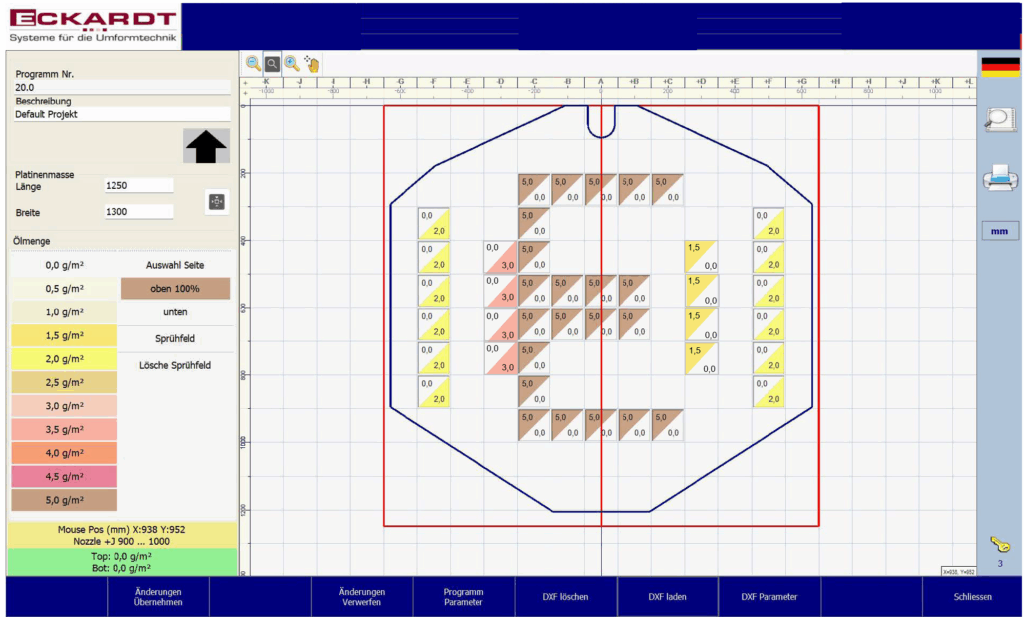

The focus of the general overhaul was to replace the spray nozzles. Until then, our standard SD 25 models had been in use, which process the material as it passes through using the “checkerboard” method. The material surface is divided into 100 x 100 mm spray fields in the spray control system, from which the top and bottom surfaces to be sprayed are selected with a mouse click. However, our customer was only able to apply the full defined quantity of spray agent – or nothing at all.

Replacement with automatic spray nozzle

To provide much greater flexibility here, we have replaced the standard nozzles with our SDA 30 automatic models. In this type, the nozzle needle is connected to a high-precision positioning motor, which means that the opening and flow rate can be infinitely adjusted. Only a few milliseconds elapse between “fully closed” and “fully open”, and each opening state in between is reached correspondingly faster.

In this way, the amount of lubricant applied can be variably adjusted for each spray nozzle and each spray field defined on the material surface. Only as much spray agent is applied to the respective area as is actually required for forming the blank. Our automatic spray nozzle has been in use worldwide for over 20 years and is continuously being developed further.

Graduated quantity allocation

41 spray nozzles are available for working each the top and bottom of the blank. In the likewise newly designed user interface, dosages of up to 3 g/m2 can be assigned in graduated steps of 0.1 g/m2 for each defined spray field.

On this basis, our customer is optimally positioned in terms of performance, flexibility and cost-effectiveness in the press shop – and we are proud and happy that we have made a decisive contribution to this with our experience in the area of retrofitting!