Lubricating copper tubes in a proper way – this was the requirement which kicked off another project falling into our category of special solutions. In this case, the customer had been relying on an inhouse construction for some time which unfortunately did not always yield the desired results.

Extensive test setup

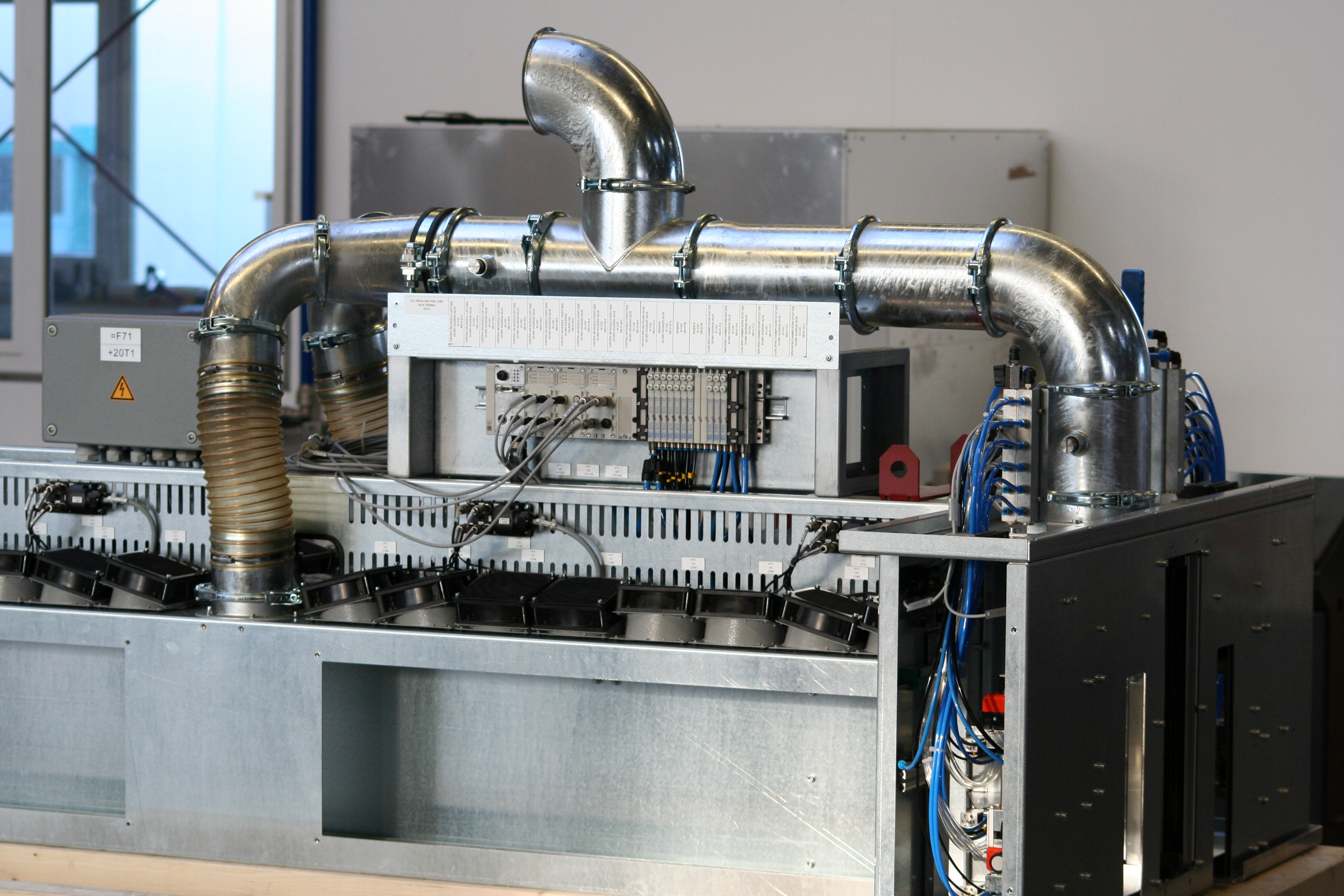

First we studied the adhesion behaviour of the lubricant when applied to copper tubes standing upright in a test setup. Based on those insights we then embarked on the construction of the new lubrication system. Its core is an EOS 1 spray unit equipped with 2×6 vertically adjustable spray nozzles which can also be moved in the direction of material flow so that the spraying requirements of various tube sizes can be met.

Dry and filter

In order to perfectly prepare the copper tubes for the subsequent processing steps the volatile oil components have to be extracted immediately following lubrication. To that end, we have constructed a drying section with 16 radial flow fans pointing in different directions on either side. The section is directly connected to the spray unit. An oil mist extraction system of our own EONA model range is included in the machine ensemble as well.

The customer uses the tube lubrication solution by Eckardt for the production of T-pieces made from copper tubes of six different nominal sizes. Another unit of identical construction has already been added.