A globally active manufacturer of vehicle exhaust systems swears by the sector lubricator from Eckardt Systems and has upgraded accordingly at its production sites in Serbia and China.

The sector lubricator is particularly suitable when the application process has to be designed very flexibly for medium to large material widths – for example, when only certain surface areas are to be processed or different types of oil are to be used. Instead of having to set up the oiling device and the lubricant supply again and again for the various requirements, this can all be done with the “on-board means” of the section oiler without any great effort.

Adjustable roller pairs

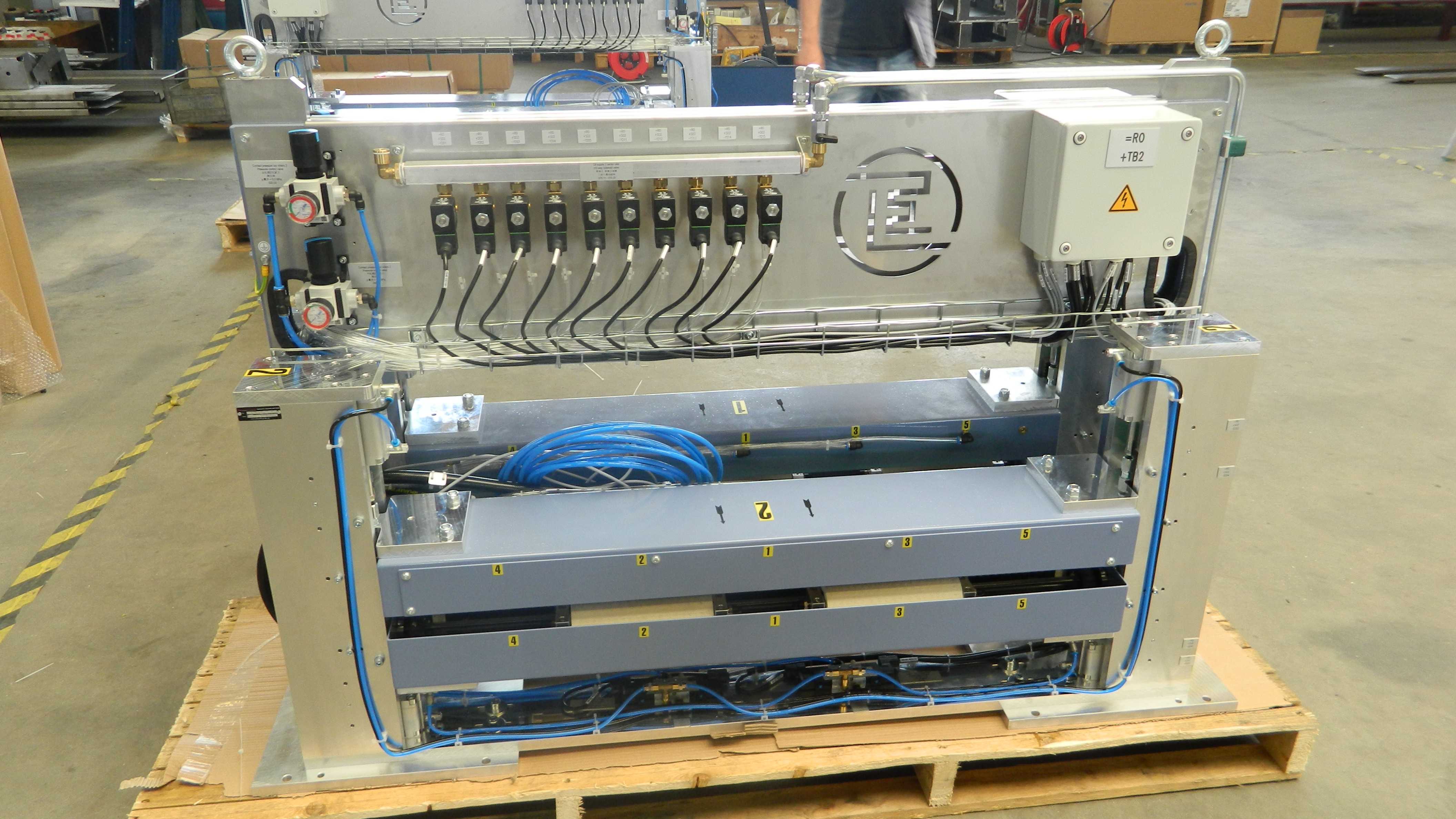

This oiling system of the SWF series from Eckardt relies on pairs of rollers (sectors) with a standard diameter of 60 mm and abrasion-resistant, perforated special felt. They are arranged in two rows one above the other and can be adjusted against each other. In the standard version, oiling widths of up to 2100 mm can be covered.

Efficient and economical lubrication

Depending on the process requirements, different pairs of rollers can be switched on and supplied with lubricant so that designated areas can be specifically covered during the process. In this way, lubrication is particularly targeted and economical, as lubricant is only applied where it is really relevant for the forming of the sheet metal part. In the configuration for our customer, two types of oil are used, which can be assigned to the different roller pairs via the control system.

The SWF sector roller lubricator from Eckardt would also be the right solution for your lubricant application requirements? Then please contact our sales team for further

information: sales@eckardt-systems.com