Accepting an out-of-the-ordinary challenge can be particularly rewarding. This is what we learned from our most recently completed project in the field of spray lubrication – a project in which we had to bring in our engineering competence to the full extent.

Building around an existing infrastructure

The customer situation: a transport system – four lanes running in parallel – moves blanks through the entire process line. Suspended from a magnetic belt conveyor, the blanks traverse the various stages in horizontal position. These structural conditions gave us a twofold nut to crack: we had to construct a suitable lubrication system around an existing transport infrastructure and had to make sure that different blank shapes and sizes can be lubricated from above and below overcoming the limitations caused by their hanging from the transport belt.

Movable “nozzle arms”

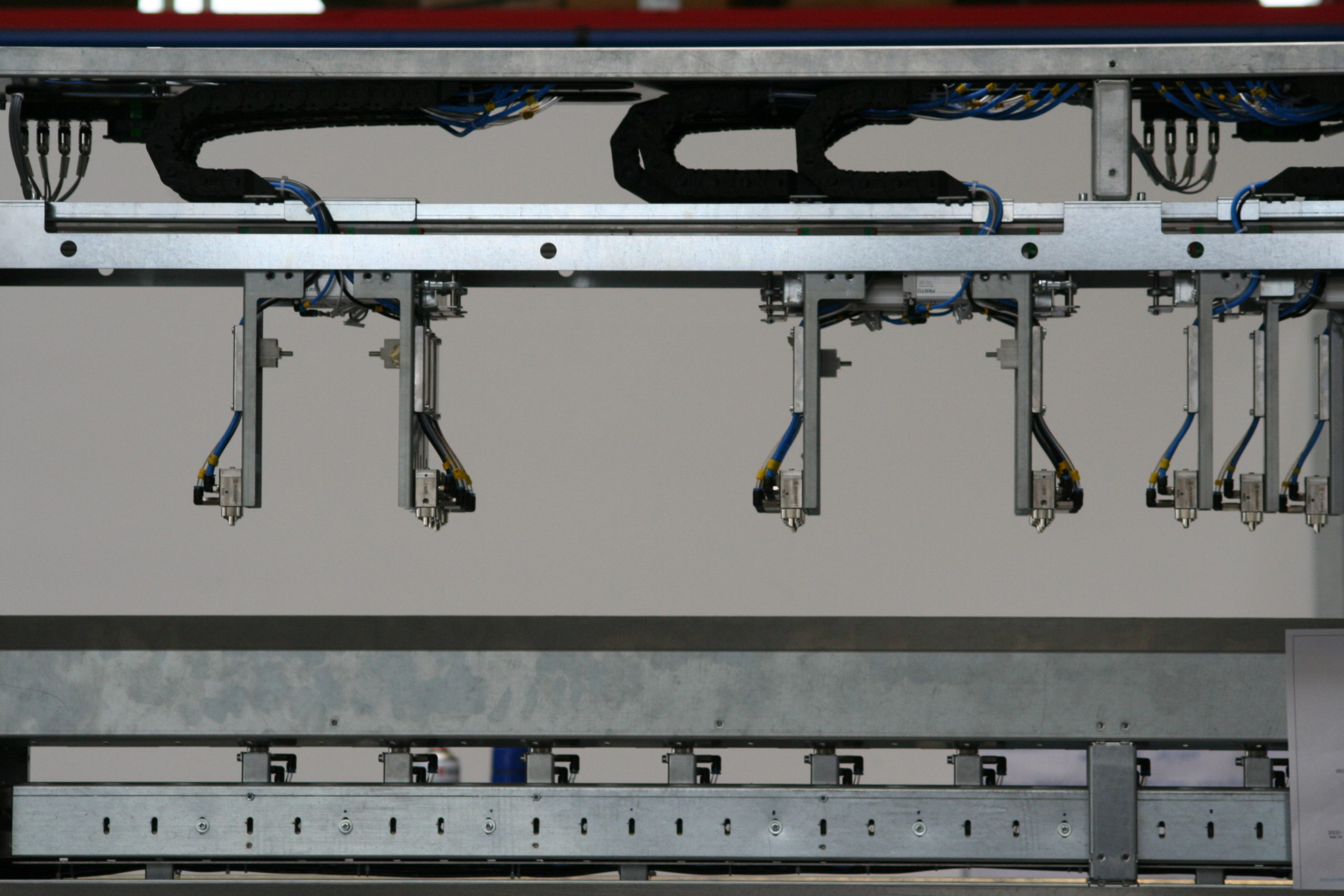

A very special variant of the spray chamber has done the trick. The lower spray bar runs across the entire spraying width in one piece, whereas the upper bar is divided up into several “spraying arms”, each of which is equipped with a spray nozzle. The arms are arranged in groups of three (or less) in the direction of traverse.

It is possible to change the position of the arms to the left and right individually, enabling them to exactly target the surface areas of the blanks required for being covered with lubricant. The respective settings are stored in the control unit of the lubricator and can be retrieved at the push of a button when there is a change of blank types and forming tools.

Eckardt spray lubricator EOS-X-P-2000

The spray lubrication system deployed is an EOS-X-P-2 model by Eckardt, laid-out for the processing of blank widths from 300 to 2.000 mm and blank lengths from 400 to almost 1.000 mm.

The unit is equipped with our tried and tested two-grade spray nozzle SD 25 HD. The nozzle contains a needle whose positioning alters the profile of the delivery port, thereby regulating the flow rate. Two units for oil mist separation ensure the quality of the surrounding air.

The very specially designed spray lubrication system is currently en route to its ship-to location in Mexico. It is really by accident that the name of the place perfectly matches the fancy machine design: Hermosillo – little beauty!