Running on missing parts is usually not what a technical device should be doing – but at times it can be exactly what is required!

Such is the case when we have to tailor the basic construction of our roller-based lubricators to particular customers’ requirements.

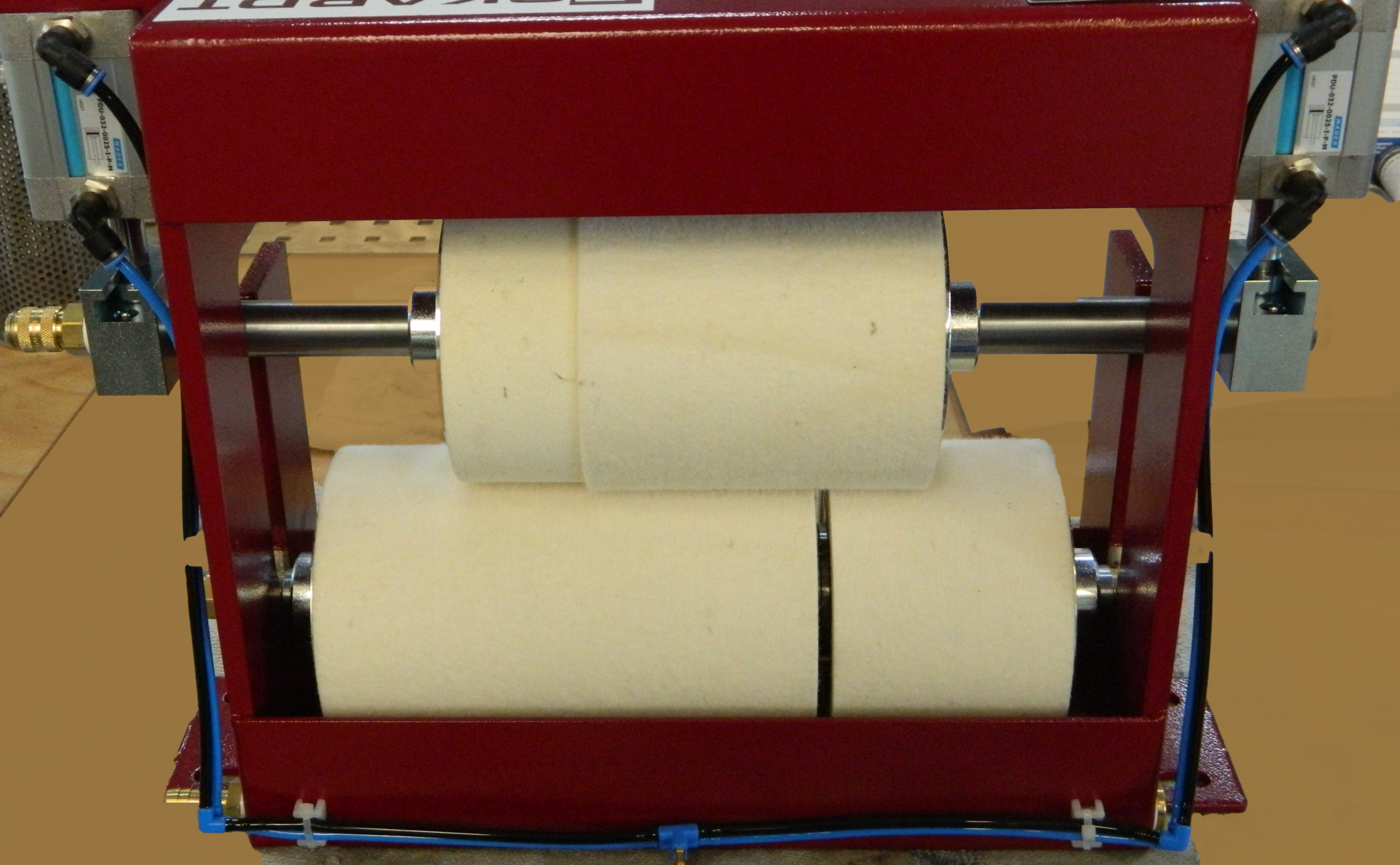

Rollers with cut-outs

For example, there are certain surface areas on the material passing through which have to be excluded from lubrication. Or the process involves pre-formed parts which have to be transported through the lubricator including their “bulges”, e.g. for the recalibration of plug parts.

Enter our cut-out rollers. While the hollow axle inside still covers the entire roller width it only releases the lubricant to the surface areas on either side of the cut-out. In this way, a pattern of lubricated and non-lubricated segments can be created exactly as required, individually for the upper and lower rollers.

Instead of cut-outs there is also the option of assembling roller segments of different diameters which also offers the possibility to process “three-dimensional” material.

Configuration example: roller-based lunbricator WF-60

The pictures show the modifications as described with reference to our roller-based lubricator model WF-60. The systems are available for a variety of lubrication widths from 100 to 1.000 mm and are recommended for use for belt thicknesses of up to 5 mm .

Among others, the WF-60 particularly plays to its strengths in the production of components for stamping and bending, milling/turning/grinding machines, stamped parts for household appliances and expanding metals for application in the energy technology, chemistry and medicine sectors.

The surface pressure against the material is regulated either by means of adjustment springs or pneumatic cylinders attached to the upper and/or lower roller.

The WF-60 is designed for use with interchangeable rollers, thereby making adjustments to different lubrication requirements particularly quick and easy. Various roller coverings can be applied, such as the standard abrasion-resistant special felt or a perforated felt for viscosities > 150 mm²/s, among others. A PU covering is also available in case one roller only serves a as belt guide and doesn‘t supply lubricant by itself.

You want to learn more about our roller-based felt lubricators? Go to the product page!