Different oil, same precision: corrosion protection is another area where our spray lubricators of the EOS series play to their strengths. In this case for the benefit of a cleaning technology manufacturer in need of a sealing solution for the metal surfaces of accessory parts.

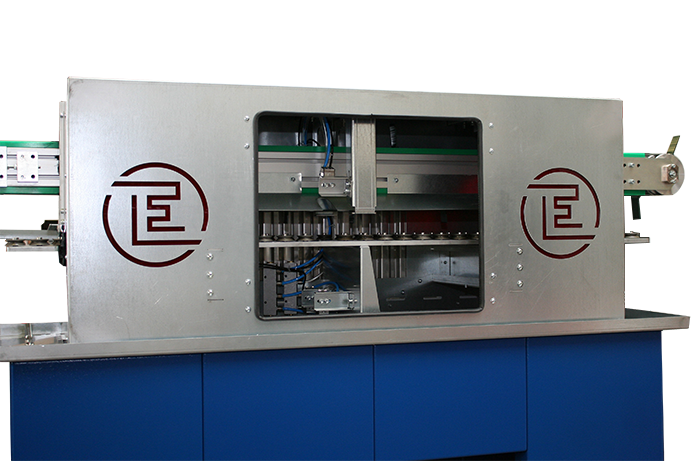

Since the inquiry was not about unprocessed blanks but fully manufactured products we had to give our standard EOS spray chamber a substantial makeover in order to ensure optimum throughput and precise surface lubrication at the same time. Finally we presented a fully integrated, compact spray system to our customer.

Conveyor technology included

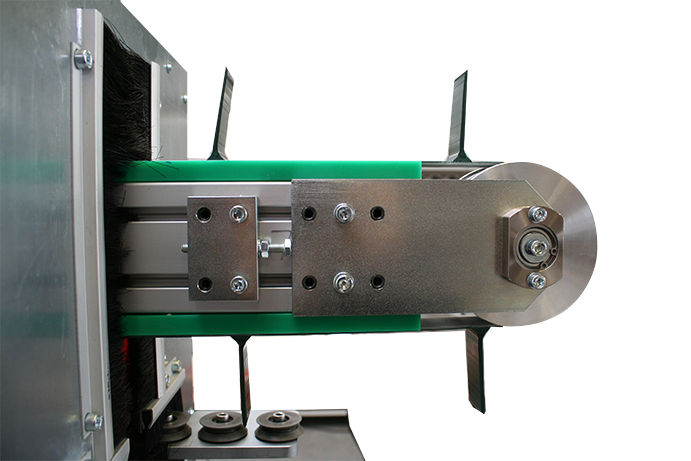

We built this particular EOS configuration around a studded belt conveyor which transports the parts through the spray chamber measuring roughly 1.20 m in length. The conveyor includes ball bearing mounted guide rollers on either side which can be adjusted to the individual part widths.

The protective oil is applied using a pair of spray nozzles mounted on both the upper and lower spray bar. The two nozzles on the upper bar can be positioned at an angle ensuring that the spray jet also covers more complex surface shapes in their entirety.

Changing the pressure of the spray air changes the degree of atomization of the protective lubricant, the quantity of which is adjusted by changing the pressure inside the 40 l supply container.

The oil mist inside the spray chamber is removed using an exhaust system which includes a centrifugal separator and a secondary filter. Overspray is collected and extracted into a separate return container. Mounted on a solid pedestal the exhaust unit can be flexibly positioned with regard to the surrounding work environment.

All in one place

An underframe right below the spray chamber hosts the entire supply infrastructure. i.e. pressurized container, return container, and valves. A slide door provides convenient access to all components making maintenance work and oil refill a walkover. The all-in spray solution also includes height-adjustable legs for perfect set up with regard to up-/downstream process infrastructure and ergonomics in the workplace.

No matter what your very own requirements: corrosion protection made by Eckardt will pay off! For more information, go to our product website, for a comprehensive project report, go to the „Case Studies“ section on our download page.